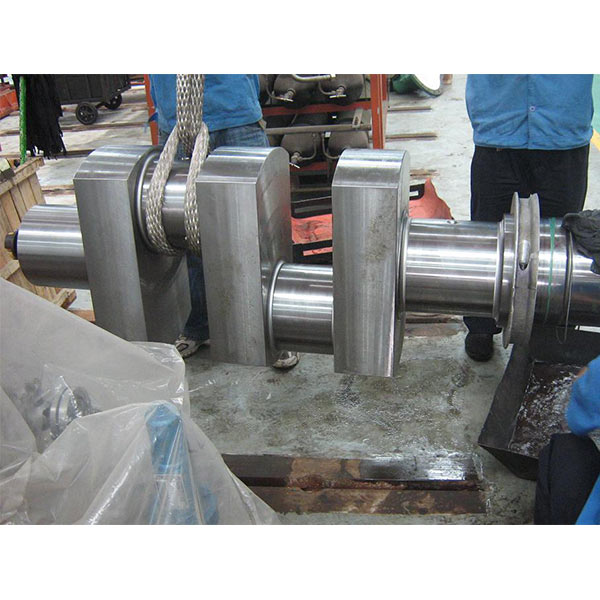

A reciprocating compressor crankshaft is a small, hardened steel component that transfers power from an electric motor to the compressor. It has a characteristic shape, oil holes, and lubrication channels that help it operate smoothly for many years. The crankshaft is made up of study cylinders with offset crankpins that link the crankshaft to the connecting rods, which then link the rods to the pistons. The offset design causes the pistons to reciprocate inside the cylinders while the crankshaft rotates.

Reciprocating Compressor Crankshaft

Crankshafts for Reciprocating Compressor

A high-quality reciprocating compressor crankshaft is typically made from strong and durable materials such as forged steel or alloy steel. These materials provide excellent strength, resistance to wear, and the ability to withstand the high stresses and forces involved in compressing refrigerant gases.

The design of a good quality crankshaft focuses on several key factors. Firstly, it needs to be precisely engineered to ensure the proper alignment of the connecting rods and pistons, allowing for smooth movement and minimal friction. This helps reduce energy loss and improves overall efficiency.

Additionally, a good crankshaft incorporates features to enhance its durability and reliability. It may include advanced surface treatments or coatings to reduce friction and wear, improving the lifespan of the crankshaft and the overall compressor. The design may also include strategically placed stress-relieving features, such as fillets and radii, to distribute forces evenly and prevent fatigue failure.

- Made with excellent quality forging steel, ensure the connecting rod has the performance of high strength, high fatigue resistance, sufficient rigidity and toughness

- Run stably and reliably, long service life, strict QC system, quality guarantee, durable in use

- Reasonable price, prompt delivery.

- Crankshafts for refrigeration compressors

Air Compressor Crankshaft

Materials

As one of the most crucial parts of a compressor, and with an appearance that directly influences the work life of the compressor, it is vital to choose crankshaft material that is capable of bearing a heavy load and changing torque. Due to that, users must choose the material based on the actual application needs of the compressor.

2. Our crankshafts are known for their rigidity, strength and impact resistance.

3. Crankshaft materials include alloy, and a roughness of Ra0.02 after polishing, giving it an excellent wear resistance and lubricity.

4. Dongyi owns and operates numerous professional detection equipment sets, including a trilinear coordinates measuring instrument, contour graph and rough meter in order to carry out strict detection processes for the degree of parallelism of the crankshaft, torsion resistance of the crankshaft and coaxiality of the two crank throw. This ensures all crankshafts rotate smoothly and with no noise, vibrations or shaking, thus ensuring a long service life for the compressor.

When in operation, it bears gas pressure,inertia force and inertia moment. It suffers form great and sophisticated stress, and as well as the impact effect of alternating load. Meanwhile, being a fast rotating component, it should be provided with enough rigidity and strength, outstanding ability to bear impact load, and excellent abrasion resistance and lubrication.

Crank is the connecting part between main journal and connecting rod journal, with cross-section being and oval. To balance the inertia force, there is a balance weight cast(or fastened) on the crank. The balance weight is used to balance the unbalanced centrifugal moment of compressor, and sometimes used to balance a part of reciprocating inertia force, thus to keep the crank running smoothly.