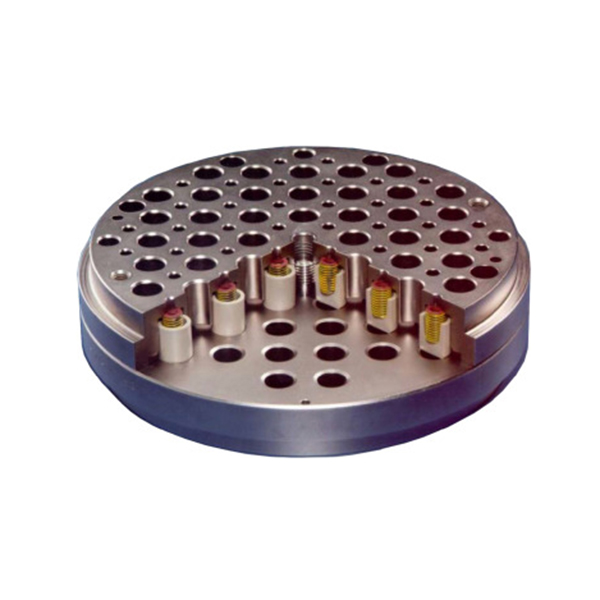

Compressor Poppet Valve

Maintenance

- Valve service without special tools, reconditioning can be done on the spot

- No need for specially trained people to perform valve service

- Re-profiling of valve seat not required thanks to the replaceable seat plate

Performance

- Outstanding performance with contaminated gases, less oil stiction

- Insensitive to different thermal expansion and humidity in the gas

- Less clogging than plate valves for dirty or wet gases

- Improved aerodynamic flow path leads to lower pressure drop and higher efficiency

- Lower noise emissions and reduced vibrations achievable

- Less sensitive to variable operating conditions

- Minimized risk of secondary damage to the compressor parts in case of a failure

- The metallic springs are protected from gas stream by the non-metallic poppet body

The entire valve includes valve seat, valve cover, valve plate (polyetheretherketone) bolts, nuts and springs. Dirt layer and make appropriate technical improvements to the valve cover and spring so that the air flow channel of the valve is not blocked by dirt under the working conditions of complex gas composition. The adhesion force between the valve seat and the valve cover is greatly reduced, so that the movement trajectory of the valve plate returns to normal. So as to achieve a good effect of increasing the service life of the valve by more than 3 times and saving energy by 5-10%.

| Compressor speed | max. 1’000 rpm |

| Pressure difference | max. 170 bar / 2’466 psi |

| Temperature range | from –200 to +220 °C / –328 to +428 °F |

| Diameter dimensions | min. 40 mm / 1.57 in, max. 383 mm / 15.08 in |

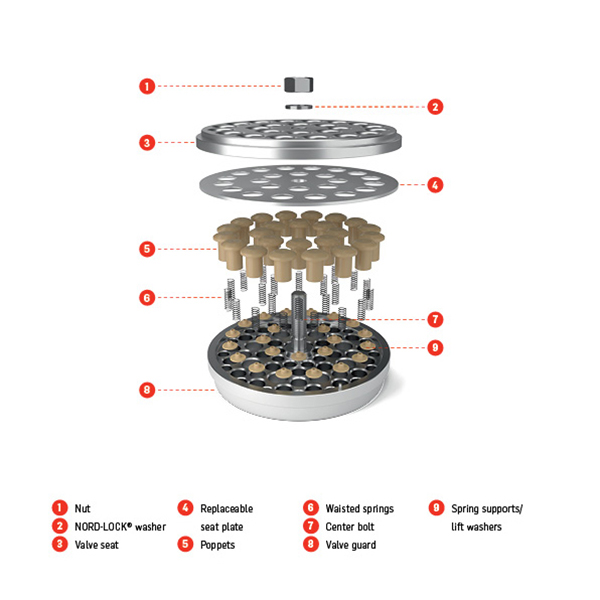

2. The mushroom-shaped head is designed spherical surface, liner contact with the sealing surface of the valve seat: perfect sealing property

3. Special hardening treatment for the sealing surface of the valve seat and the guide hole of the valve deck: reduce wear

4. Honeycomb design: the same area, the most mushroom-shaped head

5. Single valve head: easy to use and maintain

6. High-performance shock resistance PEEK mushroom-shape valve head, low wear, low noise

7. Soil Resistance: Resistance to liquid and impurities and oil viscosity, high reliability

Suitable Area:

1. Medium-high pressure condition

2. Medium-high revolution rate, Rev<1500 rpm

3. Oil/Non-oil condition

Advantages of Poppet Valves

High Efficiency:

Poppet valves are designed to provide a tight seal, minimizing leakage and ensuring efficient compression. This results in better performance and energy efficiency for the compressor.

Durability and Reliability:

The design of poppet valves allows them to withstand the high pressures and temperatures typical in reciprocating compressors. They are built to be durable and reliable over long periods of operation.

Low Maintenance:

Due to their simple design and robust construction, poppet valves generally require less maintenance compared to other types of valves. This reduces downtime and maintenance costs.

Quick Response:

Poppet valves can open and close quickly, which is crucial for maintaining the correct timing of the compression cycle and ensuring optimal compressor performance.

Compressor poppet valves are critical components in reciprocating compressors, providing efficient, reliable, and low-maintenance control of gas flow. Their ability to withstand high pressures and temperatures, coupled with their quick response time, makes them ideal for various industrial and automotive applications. Understanding the role and benefits of poppet valves helps in choosing the right components for maintaining and optimizing compressor performance.