DONGYI valves are designed for the reciprocating compressor, the gas medium would be air, Hydrocarbon gases, Hydrogen, Oxygen, Silane gases. The valves we produce have a longer service life and better flow performance.

We can offer concentric valve, ring damper valve, plate valve, PEEK valve, lamellar valve, poppet valve…

Reciprocating compressor valves are critical components in reciprocating compressors, which are widely used in various industries for compressing gases. These valves regulate the flow of gas into and out of the compressor cylinder, ensuring efficient operation.

Intake (Suction) Valves:

Function: Open to allow gas to enter the cylinder during the suction stroke of the piston.

Operation: When the piston moves down, it creates a vacuum that causes the intake valve to open, letting gas in.

Discharge (Exhaust) Valves:

Function: Open to allow compressed gas to exit the cylinder during the discharge stroke of the piston.

Operation: When the piston moves up, the increased pressure forces the discharge valve to open, releasing the compressed gas.

Plate Valves:

Description: These valves consist of a flat plate that moves back and forth to open and close ports.

Advantages: Simple design, reliable, and easy to maintain.

Applications: Common in many industrial compressors.

Ring Valves:

Description: Use multiple concentric rings that lift off their seats to allow gas flow.

Advantages: Efficient sealing, suitable for high-speed applications.

Applications: Often used in large, high-capacity compressors.

Poppet Valves:

Description: Consist of a stem and a head that moves up and down to open and close a port.

Advantages: Good for precise control of gas flow, effective sealing.

Applications: Used in smaller or more specialized compressors.

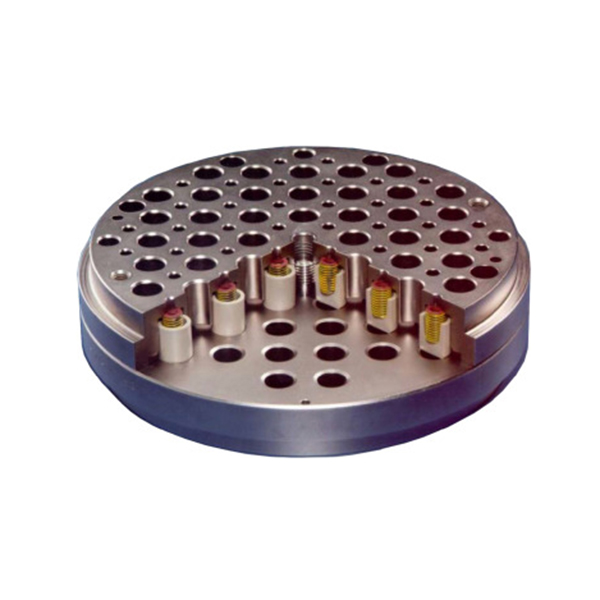

Concentric Valves:

Design: Feature multiple concentric rings that lift off their seats to allow gas flow.

Advantages: Efficient sealing, suitable for high-speed and high-pressure applications, often provide lower pressure drops and better flow characteristics.

Applications: Frequently used in high-capacity and high-efficiency compressors.

Materials Used

Steel and Stainless Steel: Common materials due to their strength and durability.

Non-metallic Materials: Such as thermoplastics (e.g., PEEK) for their high wear resistance and low friction properties.

Composites: Sometimes used to combine the benefits of different materials for enhanced performance.

Reciprocating compressor valves are essential for controlling the flow of gas within the compressor, directly impacting the compressor’s efficiency and performance. Understanding their types, functions, and maintenance requirements is crucial for ensuring the reliable operation of reciprocating compressors in various industrial applications.