Connecting rods in compressors, especially in industrial-grade ones, are typically made of strong and durable materials such as steel or aluminum alloys to withstand the high pressures and stresses involved in compressing gases. They need to be precisely engineered to ensure smooth operation and longevity of the compressor.

The Different Parts of a Connecting Rod

A connecting rod is generally composed of several parts. Here they are in no particular order:

- Small end

- Big end

- Piston

- Bearing inserts

- Bush Bearing

- Wrist pin

- Bearing cap

- Shank

- Bolt and nut

Here’s a closer look at each part of the connecting rod:

Small End

This part of the connecting rod is usually connected to the face of the piston pin.

Big End

This part of the connecting rod is usually connected to the side of the crank pin.

Piston

The piston is connected to the crankshaft via the connecting rod. The piston’s purpose is to function as a movable plug within the cylinder that forms the bottom of the combustion chamber.

Bearing Inserts

The bearing insert is the section connected to the bearing cap via the big end of the con rod. Bearing inserts come in 2 parts that fit seamlessly together on the crankshaft.

Bush Bearing

The connecting rod is connected at both ends with bush bearings. A phosphor bronze bush fitted with a solid eye is attached to the small end of the con rod.

The big end of the con rod is attached to the crankpin. The end is divided into two parts and supported over the crank-bearing shell.

Wrist Pin

The wrist pin, also called a gudgeon pin, is a hollow, hardened steel tube connecting the piston to the connecting rod. This component passes through the short end of the pivots and connecting rod on the engaged piston.

Shank

Different nuts and bolts connect the bearing cap and connecting rod. However, the applied shank can be tubular, rectangular, or circular.

Bolt and Nut

When a connecting rod is fitted with the crank at the bottom, both sides of the con rod’s big ends are fastened by bolts and nuts.

Reciprocating Compressor Connecting Rod

The primary purpose of a connecting rod in a reciprocating compressor is to convert the piston’s linear motion into the rotary motion of the crankshaft.

Connecting rods are generally made of forged steel and aluminum alloy and consist of an I-beam cross-section. This component is often precisely matched in sets of similar weights as it helps maintain the balance of the reciprocating compressor.

However, the lighter the piston and connecting rod, the greater or more profound the resulting power they generate, and the lesser the vibration since the reciprocating weight is also less.

Connecting rods transmit the power thrust from the piston to the crankpin. This is why they must be solid, lightweight, and rigid.

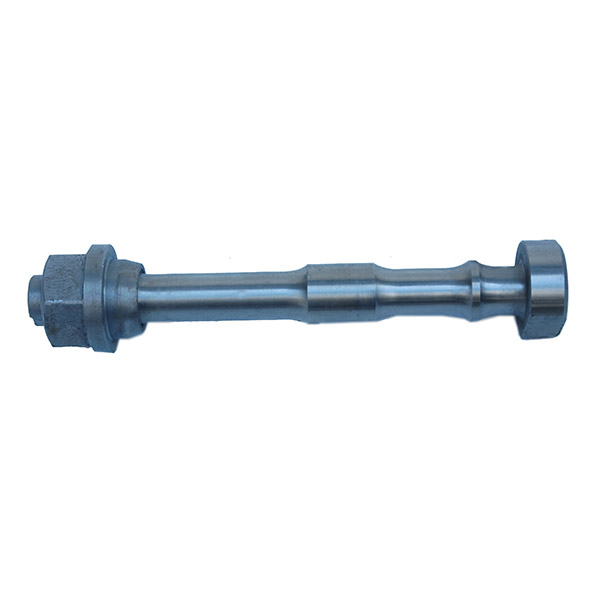

Connecting Rod Bolts And Nuts

Compressor connecting rod bolts and nuts are essential components in reciprocating compressors, which are widely used in various industries for compressing gases. The connecting rod is a critical part of the compressor’s mechanism as it connects the piston to the crankshaft, converting the linear motion of the piston into rotational motion. The bolts and nuts used to secure the connecting rod play a crucial role in maintaining the integrity and stability of the assembly.

These bolts and nuts are typically made of high-strength materials such as alloy steel to withstand the high stresses and loads experienced during compressor operation. They are designed to securely hold the connecting rod in place and withstand the forces generated by the reciprocating motion of the piston.

Connecting Rod Assembly Bushing

This bushing typically serves to reduce friction and wear between the connecting rod and the crankshaft, as well as to maintain proper alignment and stability of the connecting rod within the compressor assembly. It’s an important component for ensuring the longevity and efficient operation of the compressor.

Material:

35#, 45#, QT600, 40Cr or 42CrMoE connecting rod body;

The upper bearing is made of aluminum-magnesium alloy and Babbitt alloy;

ZCuSn10Pb1, aluminum-magnesium alloy or Babbitt alloy is used for the lower bearing bush;

The connecting rod bolts are forged with 40Cr, 35CrMoAlA or 42CrMoE.

We are a manufacturer of air compressor parts such as connecting rods, cylinders, pistons, crankpin bushings, crankshafts, etc. We use raw materials that meet standards and laboratory tested materials. Due to our extensive expertise and familiarity in this industry, we are addicted to showcasing a wide range of air compressor accessories consignments. With our accessories, spare parts and parts, you can ensure high performance, low noise and low vibration.