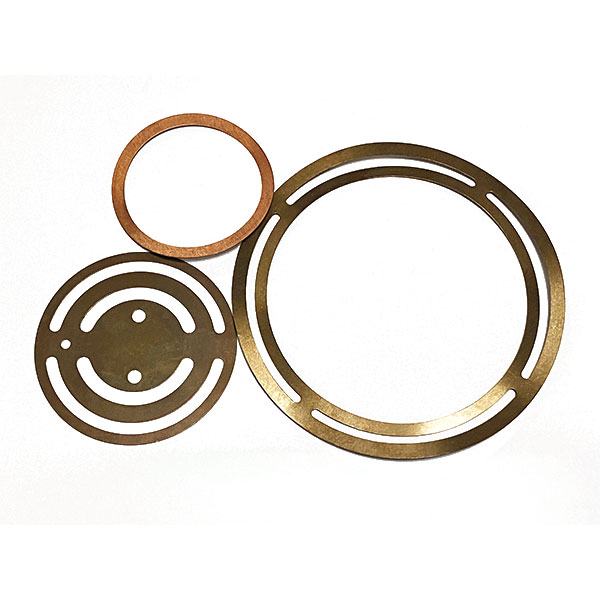

Spring Plate For Compressor

Spring plates are used in a diverse range of applications and industries and are an essential component of many different types of machinery.

The role of the spring plate in various applications is somewhat similar, whether that be a motor or a compressor. Without this component, many of the machines we know and use would not function properly in their day-to-day operations.

Uses Of Spring Plates

Machines endure a lot of movement, causing friction and buildup of heat.

Springs plates are vital to managing the rate of combustion and controlling vibration/noise that would otherwise lend to faster wear and tear or failure of a component’s role. Plates can be used as valves themselves or to provide a cushion, spring, or dampening effect.

Every application is unique, requiring different properties; meaning that what is suitable for your application may not be for another.

The primary function of the spring plate is to control the admission and discharge of gas within the compressor cylinder. It works in conjunction with suction and discharge valves to regulate the flow of gas.

2. Ensure Proper Timing:

The spring plate ensures that gas enters the cylinder during the suction stroke and is discharged during the compression stroke. Proper timing is crucial for the efficient operation of the compressor.

3. Prevent Backflow:

By sealing against the valve seat, the spring plate prevents the backflow of compressed gas, ensuring that the gas moves in the desired direction.

Design and Operation

1. Material:

Spring plates are typically made from high-strength, flexible materials such as spring steel or high-grade stainless steel. These materials can withstand repeated flexing and high stresses.

2. Structure:

The spring plate consists of thin, flexible metal strips or plates that open and close based on the pressure differential across the valve. When the pressure on one side of the plate exceeds the pressure on the other side, the plate flexes to open or close the valve.

3. Operation:

During the suction stroke, the pressure inside the cylinder drops below the pressure in the suction line, causing the suction valve to open and allowing gas to enter the cylinder.

During the compression stroke, the pressure inside the cylinder increases, causing the suction valve to close and the discharge valve to open, allowing the compressed gas to exit the cylinder.

Importance of the Spring Plate

1. Efficiency:

Proper functioning of the spring plate is critical for maintaining the efficiency of the compressor. It ensures that the maximum amount of gas is compressed with each stroke, minimizing energy losses.

2. Reliability:

A well-designed spring plate contributes to the reliability of the compressor by providing consistent operation over a wide range of conditions. This helps prevent compressor failure and reduces maintenance costs.

3. Durability:

The spring plate must withstand high cyclic stresses and harsh operating conditions. Durable materials and precise manufacturing are essential to ensure a long service life.

A spring plate in a compressor is a vital component that regulates the flow of gas in and out of the compression chamber. Made from durable, flexible materials, the spring plate ensures efficient and reliable compressor operation by preventing backflow and ensuring proper timing of gas admission and discharge. Regular maintenance and timely replacement of worn spring plates are essential to maintain the performance and longevity of the compressor.