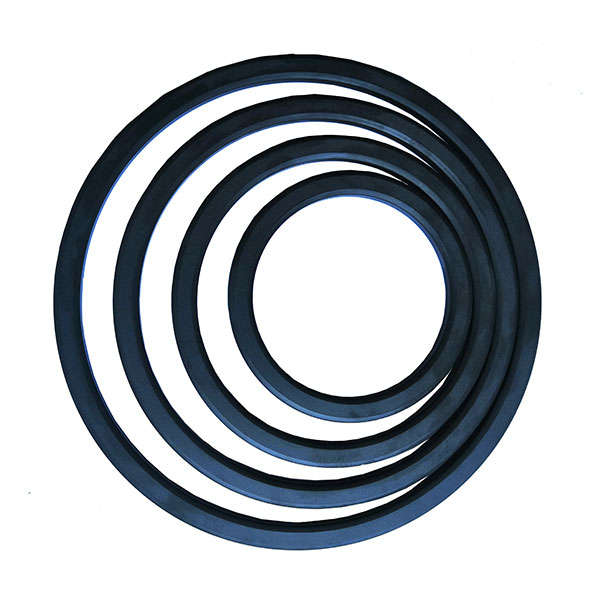

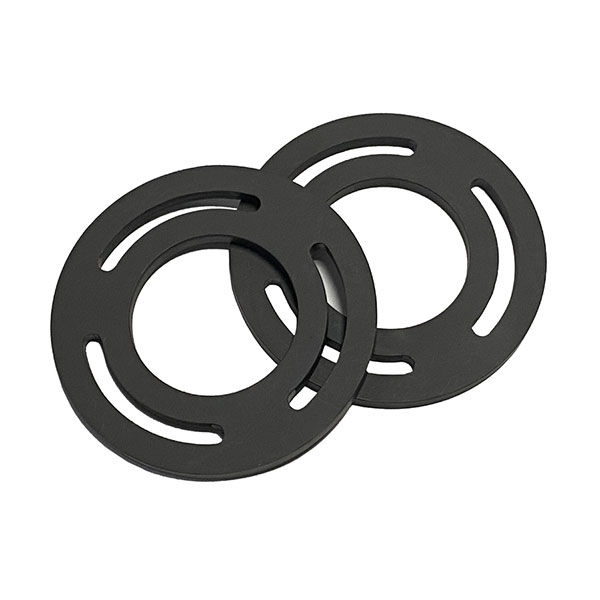

Compressor Peek Valve Plate

Main technical performance indicators of PEEK engineering plastic valve disc

| Test item | Unit | Data | Test method |

| Tensile strength Mpa | Mpa | ≥75 | GB/T1040 |

| Flexural strength Mpa into | Mpa | 入180 | GB/T9341 |

| Flexural modulus of elasticity Gpa | Gpa | ≥7.5 | GB/T9341 |

| Impact strength (unnotched) | KJ/m2 | ≥35 | ASTMD256 |

| Impact strength (notched) | KJ/m2 | ≥20 | ASTMD256 |

| Heat distortion temperature | ℃ | ≥200 | ASTMD64 |

| Rockwell hardness (HRM) | ≥100 | ASTMD785 | |

| Density | g/cm3 | 1.45 | |

| Melting point | ℃ | 334 |

1. Main performance

Melting point: 334 degrees

Tensile strength: 97.38MPa

Bending strength: 134MPa

2. Main physical properties

1. Heat resistance

The long-term continuous use temperature evaluation method, the UL temperature index measurement value is 250°C.

2. Chemical resistance

PEEK only dissolves in concentrated sulfuric acid and has good chemical resistance.

Chemical Resistance: It is highly resistant to a wide range of chemicals, including acids, bases, and organic solvents, making it suitable for use in harsh chemical environments.

Mechanical Strength: PEEK exhibits excellent mechanical properties, including high tensile strength, impact resistance, and fatigue resistance, which are crucial for components subjected to repeated stress cycles.

Low Friction and Wear: The material has a low coefficient of friction and excellent wear resistance, reducing the need for frequent maintenance and enhancing the longevity of the valve plates.

Good Dimensional Stability: PEEK maintains its shape and dimensional integrity even under high stress and temperature variations.

Benefits of Using PEEK Valve Plates

Enhanced Performance:

The superior material properties of PEEK translate to enhanced performance of the valve plates, contributing to the overall efficiency and reliability of the equipment in which they are used.

Reduced Maintenance:

The wear resistance and durability of PEEK reduce the frequency of maintenance and replacement, leading to lower operational costs and less downtime.

Longevity:

PEEK valve plates have a longer lifespan compared to those made from less durable materials, offering long-term cost benefits.

Versatility:

The ability to withstand a wide range of temperatures and chemical environments makes PEEK valve plates versatile and suitable for various applications.

In reciprocating compressors, valve plates open to allow gas into the cylinder during the intake phase and close during the compression and discharge phases to ensure the gas is properly compressed and discharged. PEEK is resistant to temperatures up to 300°C, and is resistant to water and chemicals, including hot water and steam. PEEK valve plates also have better wear characteristics, surface matching, elasticity, and sealability, which can help save energy during the opening and closing process.

PEEK valve plates are high-performance components used in demanding applications where high temperatures, chemical resistance, and mechanical strength are required. Their use in reciprocating compressors, pumps, and other fluid-handling equipment enhances the efficiency, reliability, and longevity of these systems, making PEEK an ideal material choice for valve plates.