The piston assembly includes piston body, piston lock nut, piston rod, piston ring and support ring.

The function of the piston body is to withstand the pressure of gas. In order to reduce the inertia force caused by the reciprocating motion, the piston body is required to be designed as light as possible. so we choose high-strength cast iron such as ZL108, HT250, QT400-10, QT600, 30Cr13 or some other materials for the piston body.

For piston lock nuts, we usually choose Super Nut Heated Lock Nut or Hydraulic Tension Nut. The main materials are H59, H62, 38CrMoAlA, 42CrMoE, 45#, etc.

The piston rod is made of 30Cr13, 38CrMoAlA, 42CrMoE, 40CrMoNiA, 17-7PH through high-frequency quenching, nitriding treatment or surface spraying of tungsten carbide (WC) to obtain a higher Rockwell hardness value.

The function of the piston ring and the support ring are to seal which prevent gas from passing through each other on both sides of the piston. So far our factory hassuccessfully developed PTWFE materials and obtained a patent certificate. The piston rings and support rings produced by PTWFE material have a very good service life and high cost performancewhich can meet the needs of end users under different working conditions.

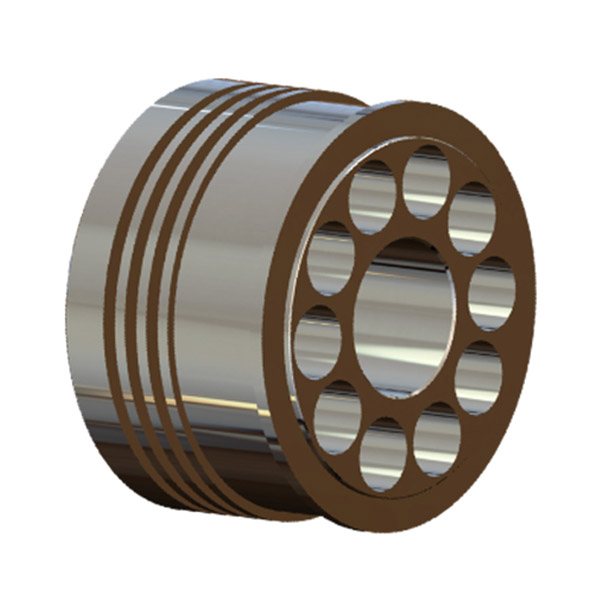

The compressor piston assembly is a critical component of a reciprocating compressor, responsible for compressing the gas within the compressor’s cylinder. It consists of several parts that work together to ensure efficient compression and operation of the compressor.

Components of Compressor Piston Assembly

The piston is the primary moving part within the cylinder. It moves back and forth (reciprocates) inside the cylinder to compress the gas. Pistons are usually made of durable materials such as aluminum or cast iron to withstand the high pressures and temperatures encountered during operation.

The piston rod (or connecting rod) connects the piston to the crankshaft. It transmits the motion from the crankshaft to the piston, causing it to move up and down in the cylinder. The rod needs to be strong and durable, typically made of steel or another high-strength material.

Piston rings are installed in grooves on the outer circumference of the piston. There are typically two types of rings: compression rings (to seal the combustion chamber and prevent gas leakage) and oil control rings (to regulate the amount of oil on the cylinder walls).

Piston Pin (or Wrist Pin):

The piston pin connects the piston to the connecting rod. It allows for the pivoting motion of the piston as it moves within the cylinder. The pin must be strong and wear-resistant, often made from hardened steel.

Gudgeon Pin Bush:

This is a bearing that supports the piston pin. It allows the piston pin to rotate freely, reducing friction and wear. The bush is usually made of a softer material like bronze to allow smooth movement and prevent damage to the piston pin.