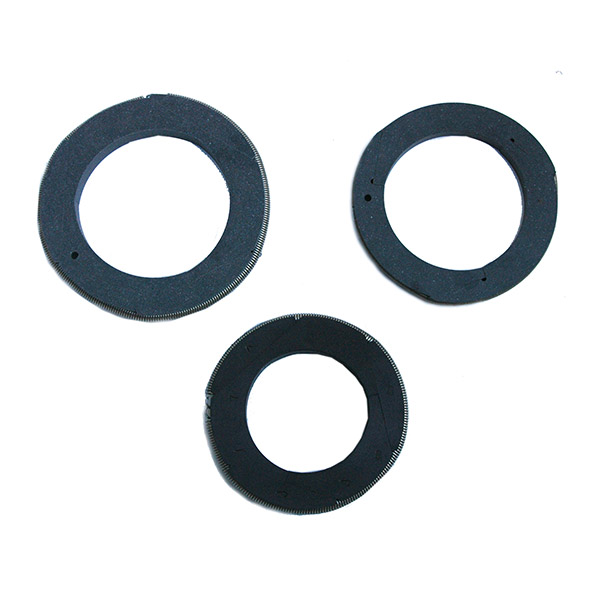

Ptfe Sealing Ring For Recip Compressor

Due to its unique molecular arrangement, PTFE has an extremely low coefficient of friction. In addition, it is non-reactive with most common gases and liquids and has excellent chemical resistance.

It can be continuously used at temperatures up to 250°C (490°F) and works well at extremely low (cryogenic) temperatures.

Reinforcing fillers, wear resistant additives and self-lubricating fillers are typically applied to enhance the properties of PTFE. Fillers are selected and combined to reduce wear and improve performance based on the specific operating environment.

Sealing:

PTFE sealing rings provide an effective seal between the piston and the cylinder wall, preventing gas from leaking during the compression process. This sealing capability ensures that the gas is properly compressed and maintains the desired pressure levels.

Lubrication Reduction:

PTFE has low friction properties, reducing the need for additional lubrication between the piston and the cylinder. This is especially beneficial in applications where oil-free operation is desired, such as in the food, beverage, and pharmaceutical industries.

Wear Resistance:

The inherent wear resistance of PTFE helps prolong the life of the sealing rings and other compressor components, reducing maintenance frequency and costs.

Chemical Resistance:

PTFE is highly resistant to a wide range of chemicals, making it suitable for use in compressors that handle aggressive or corrosive gases.

Advantages of Using PTFE Sealing Rings

Reduced Friction

One of the key advantages of using PTFE sealing rings is their extremely low coefficient of friction. This means they generate minimal frictional forces against the cylinder wall during operation. As a result, there is less energy loss due to friction, leading to improved compressor efficiency.

The piston seal provides low friction performance and long service life. It is low-cost to maintain and practically eliminate stick-slip piston movement.

Improved Wear Resistance

PTFE has exceptional wear resistance properties compared to other materials commonly used for sealing rings. The self-lubricating nature of PTFE reduces wear on the ring itself and the cylinder wall it meets during operation. This leads to increased durability and extended service life for the ring and other components with the compressor.

Effective Sealing Capability

Effective sealing between the piston and cylinder wall is crucial for maintaining compression efficiency in a compressor system. The unique properties of PTFE allow it to create a tight seal, preventing gas leakage and ensuring optimal compression performance. This results in improved overall system efficiency and reduced energy consumption.

Chemical Resistance

Compressors often handle various gases, some of which may be chemically aggressive or contain contaminants. PTFE is highly resistant to different chemicals, making it an ideal choice for sealing rings in compressors that operate in demanding environments. The chemical resistance of PTFE ensures that the piston rings can withstand exposure to corrosive gases without degradation or loss of performance.

High-Temperature Stability

Compressors can generate significant heat during operation, especially in high-pressure applications. PTFE has excellent thermal stability and can withstand high temperatures without losing physical properties or deforming. This makes PTFE sealing rings suitable for compressors operating at elevated temperatures, ensuring reliable performance even under extreme conditions.

PTFE sealing rings offer numerous advantages for recip compressors, including reduced friction, improved wear resistance, effective sealing capabilities, chemical resistance, and high-temperature stability. These benefits contribute to enhanced compressor efficiency and performance. Whether upgrading your existing compressor or selecting sealing rings for a new system, PTFE sealing rings should be a top consideration. Their unique properties make them an excellent choice for demanding compressor applications.

In summary, PTFE sealing rings in reciprocating compressors are high-performance components that provide effective sealing, reduce lubrication needs, resist wear, and withstand chemical attack. These properties make them ideal for a variety of demanding industrial applications, enhancing the efficiency, reliability, and longevity of the compressor.