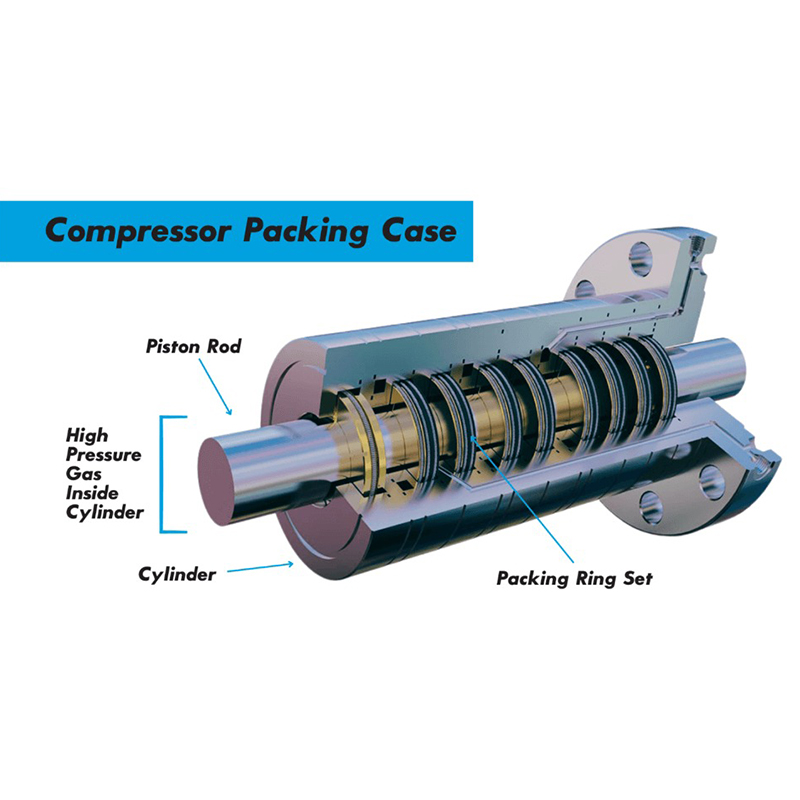

The purpose of the packing case is to prevent gas from leaking out of the compressor cylinder during the compression process. It also keeps contaminants from entering the cylinder, ensuring the compressor operates efficiently and reliably.

The packing case typically contains multiple layers of packing materials, such as rings or seals, which are compressed against the piston rod to create a tight seal. These packing materials may be made of various materials, including synthetic rubbers, plastics, or metals, depending on the specific requirements of the compressor and the gases being compressed.

Overall, the compressor packing case plays a crucial role in maintaining the integrity of the compression process and preventing leakage, which is essential for the efficient operation of reciprocating compressors in various industrial applications.

Compressor Packing Case

Compressor Packing Assembly

Precision machined from cast iron, bronze alloy steel or stainless steel.

All packing and wiper cases are designed to be easily reconditioned when needed to maximize service life.

Available in cooled or non-cooled for use in both oil-free and lubricated applications to satisfy the full spectrum of temperatures, pressures and corrosive conditions.

Designed to meet all environmental concerns and regulations including available vent and purge designed assemblies for fugitive emissions reductions.

The packing case assembly is critical to the proper operation of the piston rod packing and the sealing of the cylinder. The packing case has several important features that help to maximize your compressor’s performance:

- Cylinder-end gasket to prevent process gas from bypassing the packing rings

- Precision-machined mating and sealing surfaces to prevent leakage

- Provides passages for lubrication, vent, coolant and buffer gas as required

- Flange with adequate bolting to maintain gasket seating and seal between cups at operating pressure

- Recess in each cup to contain free floating seal rings

With the ever increasing concern for the effects upon the global environment, systems to control emissions are becoming even more important. As part of its commitment to its customers and the environment, our company has a range of purge control systems that maintain buffer pressure and monitor gas flow and packing condition to eliminate emissions from packing cases used in reciprocating compressors. The purge-gas system prevents your process gas from escaping through the packing case by introducing an inert buffer gas into the assembly.

Packing case conversion

We can convert your existing case to a purge design. Converting your packing case to a purge-gas system allows you to monitor your packing ring life and comply with tough emissions regulations. Our standard purge design employs a two groove T-cup. If the length of the assembly is limited, a single groove cup arrangement is used.

Each Dongyi packing case consists of a flange and a series of annular cups containing recesses for the packing rings. The type and material of the rings varies based on service conditions.

For up to about 2,000 psi (140 bar), the case material is normally cast iron, or Ni-Resist iron if the application involves corrosive gases. Steel or stainless steel is most common for higher pressures.