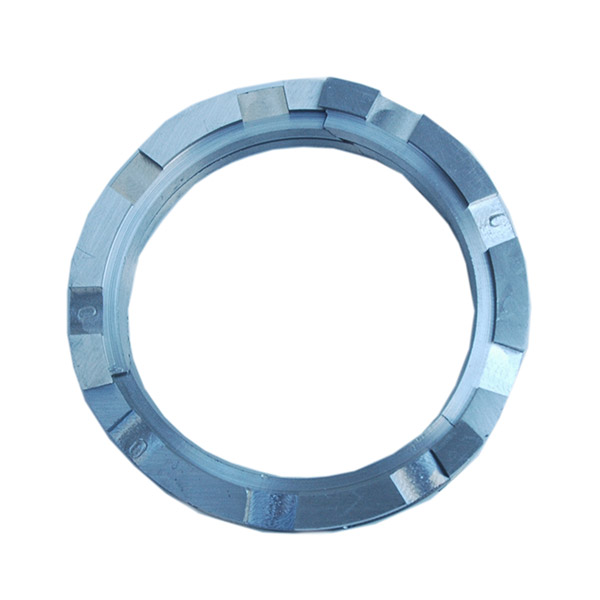

Oil Wiper Ring For Reciprocating Compressor

Oil wiper rings are important for maintaining the reliability of compressors because they prevent crankcase oil from contaminating the gas being compressed in the cylinders while still allowing the machine to be lubricated. To be effective, wiper rings must:

- Remove oil from the entire circumference of the piston rod;

- Have a drain profile that meets the machine’s specific needs;

- Be made from materials that provide a balance of strength, flexibility, and durability.

Controlling Oil Film:

Oil wiper rings scrape excess oil off the cylinder walls as the piston moves up and down. This ensures that a thin, consistent film of oil remains, which is essential for lubrication and reducing friction between the piston and cylinder.

Preventing Oil Consumption:

By limiting the amount of oil that reaches the combustion chamber (in engines) or the compressed gas space (in compressors), oil wiper rings help minimize oil consumption and prevent oil from mixing with the gas or fuel. This is crucial for maintaining the efficiency and performance of the compressor or engine.

Ensuring Proper Lubrication:

While they prevent excess oil from entering the combustion or compression space, oil wiper rings also ensure that sufficient oil is present to lubricate the piston and cylinder walls, reducing wear and extending the lifespan of the components.

Design and Operation

Oil wiper rings are typically located below the compression rings on the piston. Their design may include the following features:

Grooved or Slotted Structure: These features help the rings effectively scrape off excess oil and guide it back to the crankcase or oil sump.

Expander Springs: Some oil wiper rings incorporate expander springs to maintain proper contact with the cylinder wall, ensuring consistent oil control throughout the piston's movement.

Material: Oil wiper rings are usually made from durable materials such as cast iron or steel, often with surface treatments like chrome plating to enhance wear resistance and reduce friction.

In summary, oil wiper rings are vital for controlling the lubrication oil on the cylinder walls, ensuring efficient operation of reciprocating compressors and internal combustion engines by preventing excessive oil consumption and maintaining proper lubrication. Regular maintenance and timely replacement are key to their effective performance.