Connecting rod bearings play a crucial role in the operation of compressors by providing a low-friction surface for the connecting rods to pivot on as they move in a circular motion. These bearings are typically made of durable materials such as steel or bronze and are designed to withstand the high pressures and temperatures encountered in compressor applications.

Compressor Connecting Rod Bearings

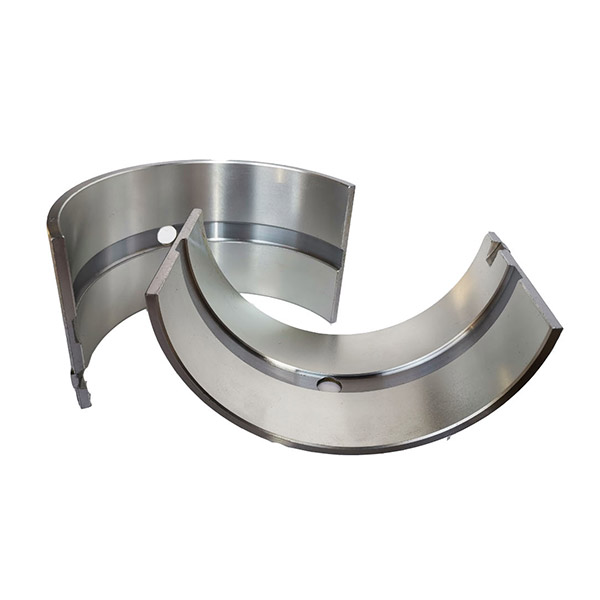

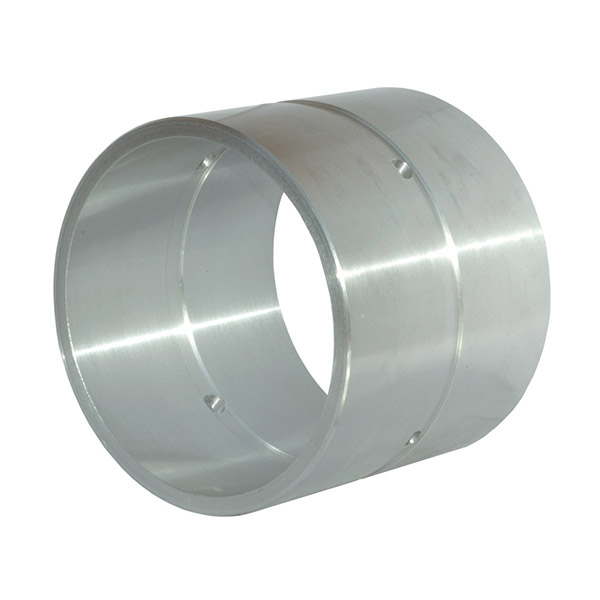

Connecting rod bearings provide rotating motion of the crank pin within the connecting rod, which transmits cycling loads applied to the piston. Connecting rod bearings are mounted in the big end of the connecting rod. A bearing consists of two parts (commonly interchangeable).

Location – Connecting rods are located between the piston wrist pin at the top end and the crankshaft journal on the bottom end, transferring power and motion between the two components. The bearings are fitted into the rod and end cap to surround the crank journal.

Purpose – The main job of connecting rod bearings is to smoothly transfer the reciprocating motion of the pistons into the rotating motion of the crankshaft while also withstanding tremendous pressure and heat. They must maintain a thin oil film along the shaft journals to separate surfaces and prevent metal-to-metal contact to reduce friction and prevent rapid wear or failure. Proper lubrication keeps friction low even with extremely heavy loads during combustion.

Power Stroke Initiation: The process begins when the piston moves downwards during the power stroke. As the piston descends, it compresses the air or gas in the cylinder. This compression generates a force that needs to be transferred to the crankshaft to produce rotational motion.

Connection to the Crankshaft: The connecting rod is attached to both the piston and the crankshaft. At the lower end of the connecting rod, there is a bearing that connects it to the crankshaft. This bearing allows the connecting rod to pivot as the crankshaft rotates.

Transfer of Pressure: As the piston reaches the bottom of its stroke, the compressed air exerts pressure against it. This pressure is transmitted through the piston to the connecting rod. The connecting rod, in turn, transfers this pressure to the crankshaft through the connecting rod bearing.

Rotational Motion: The pressure applied to the connecting rod bearing causes it to push against the crankshaft. This force is transmitted along the length of the crankshaft, causing it to rotate. As the crankshaft rotates, it converts the linear motion of the piston into rotational motion, which is essential for driving the compressor.

Friction Reduction: The connecting rod bearings are typically lubricated to reduce friction between the connecting rod and the crankshaft. This lubrication ensures smooth movement and minimizes wear and tear on the components, allowing the compressor to operate efficiently and prolonging its lifespan.

In summary, compressor connecting rod bearings play a crucial role in transferring power from the piston to the crankshaft. They facilitate the smooth movement of the connecting rod and help to minimize friction, ensuring efficient operation of the compressor.

Connecting rod bearings support, guide and connect the connecting rods to the crankshaft, which move against each other. In this way, the linear stroke movements of the piston and conrod can be translated into the circular rotary movements of the crankshaft.

Connecting rod bearings support, guide, and connect the connecting rods to the crankshaft in an air compressor. The connecting rods convert the reciprocating motion of the pistons into rotary motion, which contributes to the compressor's performance and efficiency. The bearings can be roller bearings, plain bearings, or other types, depending on the compressor's design and requirements